Fascination About Mhs - Material Handling Supply Inc.

Fascination About Mhs - Material Handling Supply Inc.

Blog Article

The Buzz on Mhs - Material Handling Supply Inc.

Table of ContentsMhs - Material Handling Supply Inc. for BeginnersTop Guidelines Of Mhs - Material Handling Supply Inc.The Only Guide to Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. Fundamentals ExplainedSome Known Details About Mhs - Material Handling Supply Inc. The Only Guide for Mhs - Material Handling Supply Inc.6 Simple Techniques For Mhs - Material Handling Supply Inc.The Basic Principles Of Mhs - Material Handling Supply Inc.

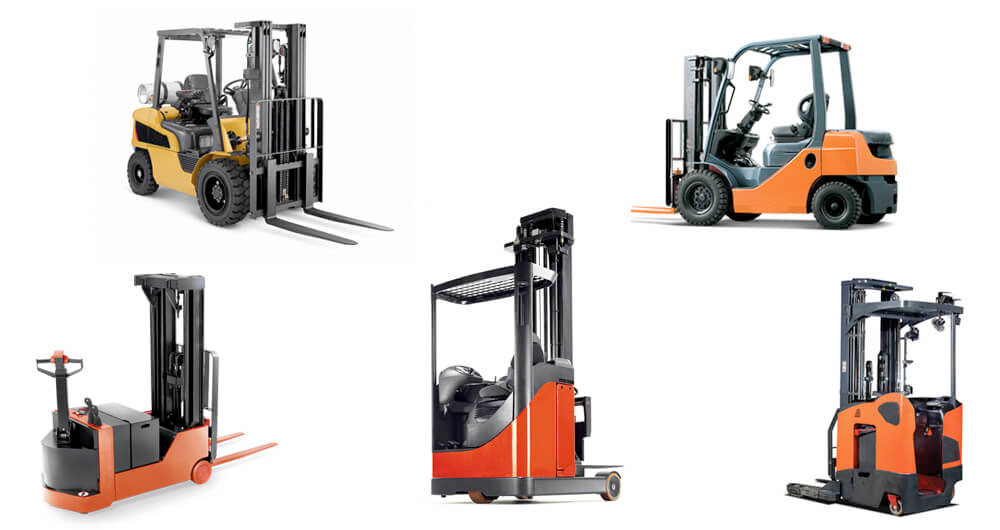

Instead, they are made use of to elevate loads just sufficient to permit horizontal motion. There are two different kinds of forklift trucks in this team: straight-mast and extended-reach.These forklifts are made use of for relocating and stacking ISO common containers for the delivery sector. These forklifts are made use of to take care of lumber, steel bars, pipes, and various other lengthy items. Unlike other forklifts, they don't have front uprights that can obtain in the means of loading and discharging.

What Does Mhs - Material Handling Supply Inc. Do?

They are installed onto vehicles to enhance the loading and discharging process. A lot of forklifts have a three-point suspension system that consists of two front wheels and a pivot point at the back axle.

If the lift is moving on or backward or parked on a slope, its facility of gravity shifts. In this instance, the forklift's center of mass falls outside the stability triangle. The outcome: the lift will topple. A forklift's center of mass relocates whenever a lift operator accelerates, brakes, or transforms.

Excitement About Mhs - Material Handling Supply Inc.

Understanding what are the different sorts of forklifts is just the beginning. https://padlet.com/tannergraves30677/my-shiny-padlet-ndr72ml43zauiw8y. Prior to you can operate any type of forklift, you need to be effectively trained to do so. This isn't simply a referral: it's the legislation. Companies are needed to supply OSHA-approved training to their employees at no charge. This training procedure must include all different forklift kinds made use of in your company

Forklifts are rated for loads at a specified optimum weight and a defined forward facility of gravity. Makers procedure and test forklifts and assign these specs to secure operators from accidents and rollovers. A lot of storage facility forklifts have lots capabilities between one and five bunches. Some bigger forklifts can raise to 50 loads (these are suggested for much heavier commercial applications such as delivering containers).

Rumored Buzz on Mhs - Material Handling Supply Inc.

In the United States, Occupational Security and Health Management (OSHA) controls making use of powered forklifts and mandates drivers should go to least 18 years old. Furthermore, OSHA requires forklift operators to finish training certification every 3 years. Many forklifts have a power resource to do the hefty training and handling.

LPG forklifts can be made use of indoors since they run silently and do not release high quantities of dangerous emissions. Diesel: Diesel forklifts provide more power and lift capacity than LP forklifts, and they are much better matched for outside applications since diesel emissions require constant ventilation.

The Only Guide to Mhs - Material Handling Supply Inc.

Harsh surface forklifts are created for outside usage on unequal surfaces. Their tires are usually much bigger and have extra gripping grip (they look comparable to heavy building and farm equipment tires). Some rough surface forklifts have stabilizers to give published here added security assistance. 8 typical kinds of forklifts are listed here.

How Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.

Pallet jacks are the simplest and many basic forklift style featuring two forks commonly 20 1/4 inches or 27 inches broad. Their standard function is restricted to moving pallets inside a storage facility. Pallet jacks usually have steering wheels in the front, and each fork has either a single wheel or 2 bogie wheels.

Many pallet jacks are made to manage roughly 5,000 pounds generally, and some designs have the ability to lift up to 8,000 lbs. There are 3 typical sorts of pallet jacks: Manual pallet jacks are hand-powered by the driver and made use of to lift, reduced, and steer pallets from one location to an additional.

Unknown Facts About Mhs - Material Handling Supply Inc.

They are frequently made use of in retail and warehousing procedures - forklift dealer watkinsville, ga. Powered pallet jacks (likewise called electric pallet trucks walkies and power jacks) resemble hands-on pallet jacks in style, however, they feature an engine that enables lifting and moving of heavier and stacked pallets. Some powered pallet jacks include a platform for the driver to stand upon while utilizing it

They include sturdy structures and pneumatic tires to fit a broader series of surface types. Walkie stackers are another basic style featuring a pole that allows lifting hauls to higher elevations than pallet jacks. Walkie stackers are frequently said to be a combination of a pallet jack and forklift - since they have a straightforward layout and take care of (similar to a pallet jack) while providing reach (comparable to a forklift).

Operators typically overview and steer the walkie stacker around the stockroom by drawing the manage. Most walkie stackers are created to take care of between 2,000 and 3,000 pounds generally, with some designs raising to 4,000 pounds (forklift rental watkinsville, ga). Raise heights differ based on make and model and normally vary in between 6 and 14 feet

The Ultimate Guide To Mhs - Material Handling Supply Inc.

Report this page